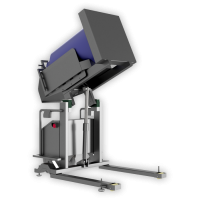

Tippers for barrels

BMB200 model was specially developed for tipping barrels with both loose and liquid products. Special shape of the tray prevents overflowing of liquid on the sides. The standard tipper works with 200-liter barrels, but we are able to adapt it to other barrel capacities. Its mobile base enables movement between workplaces in the production hall. The stabilizing feet keep the machine leveling during work.Due to the individual configuration of tippers, please send your inquiry by email: info@boxmech.eu.

| Art number: | BMB |

|---|---|

| Standard tipping height: | about 1000mm |

| Max load: | 600 kg |

| Power: | mains supply 400V or battery (supplied with charger) |

| Material: | stainless steel INOX |

| Tipping angle: | from 0° to 115° |

| Base: | mobile- wheels with brakes |

| Container handle: | circumferentially |

| Options: | lowering lights, protective mesh |

- BASEThere are two tipes of base for our tippers. The BOXMECH tipper can be mobile or stationary. Stationary tipper are being levelled and placed on 4 feet at the place of work. Customers who want to use the machine in one and the same place decide on this solution. If there is not enough space in the hall or you need to move the machine between the rooms, we offer a tipper with a mobile base on wheels with brakes. There is also an option to choose stabilizing feets extending during the work. There are used to stabilize the machine.

- POWERWe offer two types of power supply: battery (with charger) or mains power supply 400V. Battery powered tipper gives maximum independence and comfort of work when there is no constant power supply or we just want to avoid „tangling” cable. On the other hand, the mains power supply ensures more power of the tipper and guarantees its readiness to work even if someone forgets to connect the tipper to the charger before.

- CONTROLThe machines have two independent switches on both sides, so they are very adjustable. Working at the table is never a problem. As a standard, we also add a remote control on the cable so that the operator can control the level and rate of tipping at any time.

- DUMPING HEIGHTW are able to adjust the tipper to the expected level, depending on the height you want to dump the content of the container. Our standard machines dump o to a height from 950mmm to 1300mm. If you need to dump the bin higher, we offer the pole tipper.

- LOADOur tippers are able to lift a weight of up to 900 kg in a standard option, but if a weight of e.g. 1500 kg is required – then we add another servomotor that will ensure maximum fluidity and safety.

- MATERIALDue to the fact that 90% of our customers are food processing companies, BOXMECH tippers are produced only from stainless steel INOX. All machine components- the wheels, the structure, servomotor and dump tray are made of stainless steel. At the customer’s request we can electropolish the entire machine or selected parts.

- TIPPING ANGLEThe standard tipping angle for our machines is 100 ° -115 °. This parameter can be changed depending on the customer’s needs.

- SERVOMOTORAs one of the few manufacturers of tippers in the world, we use our own servomotors for our machines. Thanks to this we are sure that the servomotor is appropriate and well adapted to the dedicated loads.

- CONTAINER HANDLEMany containers, despite generally accepted standards, differ in details. We adjust the container handle so that it is maximally compatible with the container, that is being tipped. If you want to tipp on a wider or longer side – we will also adjust the dimensions of the container received from you.

- LOWERING SIGNALOur tippers meet all health and safety requirements. Each tipper is equipped with an audible lowering signal as standard. On request, we can also install traffic lights or a protective mesh that will give the highest safety standards for your employees.

- WORKING TABLEWe are able to design additional accessories for all tippers, such as working table, which do not only extend the discharge, but also adjust its final height.

© Boxmech.